Barcode Color Selection Considerations

When barcode symbols are integrated into packaging design, color selection is a critical technical consideration that directly affects scannability. Understanding how barcode scanners interpret color—and which combinations meet industry standards—is essential for ensuring reliable point-of-sale performance.

How Barcode Scanners Interpret Color

Barcode scanners operate by emitting a red laser beam (typically 630-680 nm wavelength) and measuring the intensity of reflected light. The scanner does not “see” colors in the conventional sense. Instead, it measures reflectance values—the amount of light returned from the surface. Dark bars absorb the red light and return low reflectance values, while light spaces reflect the red light and return high reflectance values. The scanner interprets this difference in reflectance to decode the bar-and-space pattern.

The measure of this reflectance differential is called Print Contrast Signal (PCS), calculated as the difference between the maximum reflectance (light spaces) and minimum reflectance (dark bars). Industry standards specify a minimum PCS of 0.50 (50%), though a PCS of 0.80 (80%) or higher is recommended for optimal scan performance across varied retail environments.

Standard Color Combination: Black on White

Black bars on a white background remain the industry standard for barcode symbols because this combination produces the maximum achievable PCS. Black ink typically has a reflectance value near 0%, while white substrates approach 100% reflectance under red light. This pairing is explicitly recommended in the GS1 General Specifications as the baseline for barcode symbol printing.

Alternative Color Combinations

When packaging design constraints require deviation from black on white, color selection must account for how different hues interact with red laser light. The key principle is spectral response: colors containing cyan (blues, greens) absorb red light and register as dark to the scanner, while colors containing magenta and yellow (reds, oranges, yellows) reflect red light and register as light.

Acceptable bar colors include black, dark blue (Reflex Blue, Process Blue), dark green (Pantone Green), dark brown, and violet. Acceptable background colors include white, yellow, orange, and red. These combinations maintain sufficient contrast under red illumination.

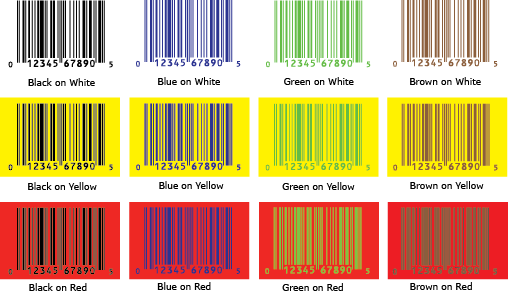

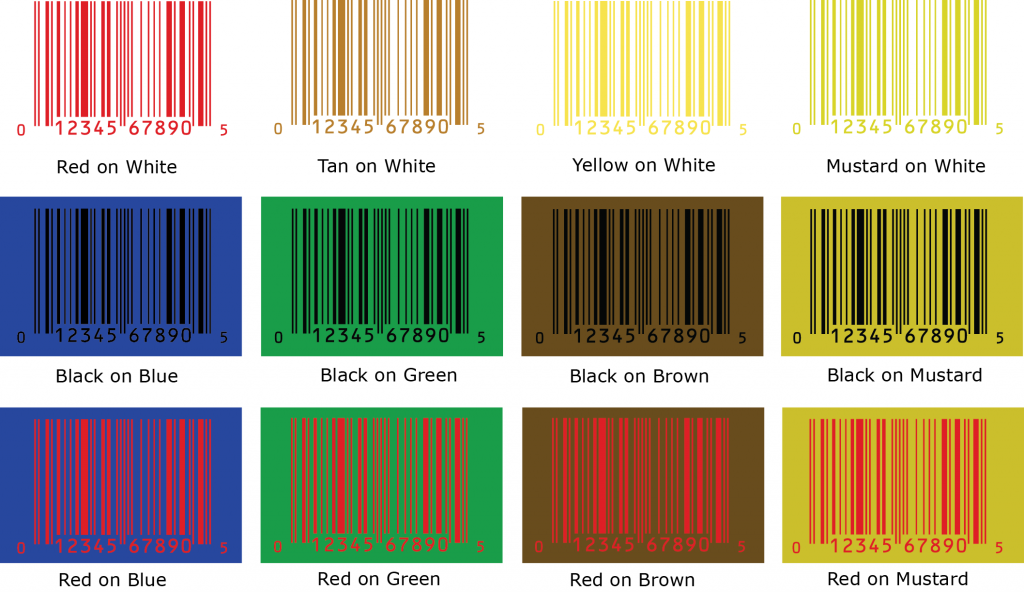

Verified scannable combinations include:

- Dark blue bars on white, yellow, or orange backgrounds

- Black bars on red or orange backgrounds

- Dark green or dark brown bars on white or yellow backgrounds

- Black bars on any light background (white, cream, pale yellow)

The UPC Color Guide provides visual examples of both scannable and non-scannable combinations. For precise color matching, the Bar Code Graphics Guide to Color Selection includes a comprehensive Pantone reflectance chart with PCS calculations for specific color pairs.

Non-Scannable Color Combinations

Certain color combinations fail to meet minimum PCS requirements due to their spectral properties:

Red, orange, or yellow bars on light backgrounds: These warm-spectrum colors have high red reflectance values (typically 70-90%), similar to white backgrounds. The resulting PCS is insufficient for reliable scanning.

Inverted barcodes (light bars on dark backgrounds): Standard barcode symbologies specify dark bars on light backgrounds. While some specialty scanners support inverted reading, most retail point-of-sale scanners cannot decode reversed polarity symbols.

Dark bars on dark backgrounds: Combinations such as black on blue, black on green, or black on brown fail because both elements absorb red light, producing similar low reflectance values with inadequate differential.

Problematic substrate conditions: Metallic inks, holographic finishes, transparent materials over dark products, and patterned backgrounds all introduce variable reflectance that interferes with consistent bar/space differentiation.

Print Quality Verification

Color selection represents only one variable in barcode print quality. Substrate type, ink formulation, printing method, and environmental conditions all affect final reflectance values. Even theoretically acceptable color combinations can fail if printing quality is substandard.

Barcode verification using ISO/IEC 15416-compliant equipment measures actual PCS values, edge contrast, and other print quality parameters under standardized conditions. Third-party testing services such as Identification Labs can validate barcode symbols against GS1 specifications before production, identifying potential scan failures that may not be apparent through visual inspection alone.

Color guidelines provide a framework for barcode design, but verification testing remains the definitive method for ensuring retail compliance.

Comments are closed.