ANSI/ISO Barcode Print Quality Grade

The key to determining the print quality and checking the proper formatting of a barcode is evaluating it in accordance with the ANSI/ISO criteria used all over the world.

The Math Behind the Grade

Every time a barcode verifier scans a barcode, it will produce raw data that can be displayed as you see below. We refer to this as the Scan Reflectance Profile.

The scan reflectance profile is what a barcode verifier sees when it scans the barcode. The image above is a single scan of a Linear UDI Barcode. The high points are the light spaces, and the low points are the dark bars. Many of our clients make an easy mistake when interpreting barcode print quality – they forget that the verifier doesn’t see the same way a person does.

The scan reflectance profile is what a barcode verifier sees when it scans the barcode. The image above is a single scan of a Linear UDI Barcode. The high points are the light spaces, and the low points are the dark bars. Many of our clients make an easy mistake when interpreting barcode print quality – they forget that the verifier doesn’t see the same way a person does.

There are nine attributes (or parameters) that are evaluated through a verifier scan according to the ISO/IEC 15415 and 15416 specifications. These attributes and their grades, or scores, are derived from the scan reflectance profile.

Five of these attributes are subject to pass/fail criteria (A or F). Each of the remaining four attributes is graded A, B, C, D or F. The overall grade for the scan reflectance profile (or single scan path) is the lowest grade for any of the nine attributes. The formal verification of a UPC symbol requires ten scan reflectance profiles spaced along the symbol. The overall symbol grade is obtained by averaging the grades of the individual scan reflectance profiles.

For example, if the ten individual profile grades were C, D, B, B, A, C, B, B, A and C, the symbol grade would be B. To be minimally acceptable, a UPC symbol must have a barcode print quality grade of C or higher. Pictured above is an example of a 10 scan read.

In general, symbols with higher quality grades can be expected to scan more easily and quickly than lower quality symbols of the same magnification. Larger magnification, the absence of truncation, and high print quality contribute to fast, effortless scanning. Symbols that fail verification may scan easily under ideal conditions, but badly or not at all in other environments. High productivity is synonymous with high symbol grades. Lower grade levels, although satisfactory, may cause failure to meet productivity goals in less than optimum environments.

Verification Report

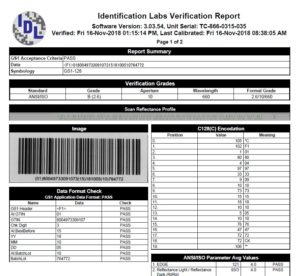

A verification report is the diagnostic output of a barcode verifier. Different software may format Scan Reports differently, but all provide a detailed analysis of the barcode print quality. Pictured is an example of the reports our Identification Labs work with every day.

We at Bar Code Graphics and Identification Labs encounter many businesses that believe that an app on a phone or a scan at the grocery store can tell them if their barcode print quality is sufficient.

Unfortunately, there are many potential barcode print quality problems that apps and scanners may not identify. These problems can result in costly charges, loss of productivity and supply chain problems.

Don’t leave losses up to chance. Let our Identification Labs help your business avoid costly issues and delays. Contact us today for certification and continuing evaluation of your barcodes.