At this year’s GS1 Connect 2025 conference, the adaptation and implementation of GS1 Digital Link took center stage as industry leaders shared real-world insights from their pilot programs. The key message was clear: by 2027, traditional barcodes will be joined by QR codes that can hold much more information. This shift, called “Sunrise 2027,” represents a transformation of how products communicate with stores, supply chains, and consumers.

What Makes This Change Different?

Traditional barcodes only hold basic product information like the Universal Product Code (UPC). The new 2D barcodes can store dozens of data points including expiration dates, batch numbers, serial numbers, and website links. This GS1 Digital Link technology turns every product package into a smart data carrier.

Steven Keedie of GS1 Global Office, who helped lead the panel, reminded attendees that the industry doesn’t have decades to refine this transition like it did with 1D barcodes. “With the UPC, we had 30 years to get it straight. Now we’re living in a dual-barcode world,” he said. “The 2D barcode is going to be multi-purpose — not just for the consumer, but for POS, for regulators, and for the supply chain. And that requires collaboration, standardization, and testing.”

He also clarified a common misconception: UPCs aren’t going away. “We’re not sunsetting the UPC. There will always be exceptions,” Keedie said. “But once we reach 90% readiness at retail, brands can start reclaiming their real estate by using a single 2D.”

“It’s not a switch to flip,” said Ryan Vann, senior director of Data Governance, Supply Chain at The Coca-Cola Company. “It’s more like a dial that we’re going to be turning slowly. 1D barcodes aren’t going away anytime soon.” This gradual approach helps companies and retailers prepare without disrupting current operations.

The Critical 50mm Rule: Why Distance Matters

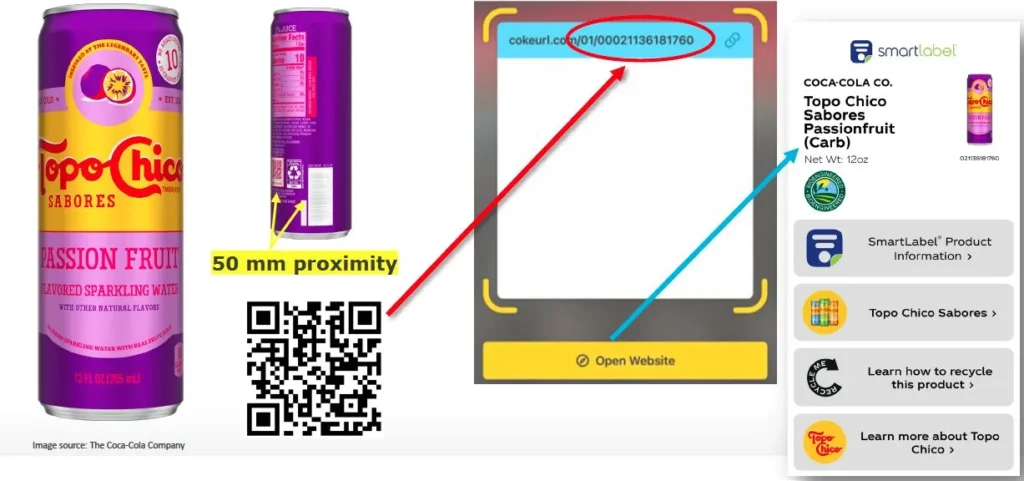

One of the most important technical requirements during this transition is the 50mm rule. When both old-style barcodes and new QR codes appear on the same package, they must be placed within 50 millimeters (about 2 inches) of each other to prevent double scanning.

“If you have too much separation between the 1D and 2D barcodes,” warned Chuck Lasley from Dillard’s, “you may capture them as two separate items and essentially double ring that item.” This problem becomes critical in busy grocery stores where cashiers scan items quickly.

Wegmans’ Wawrzyniak emphasizes that scanner speed makes proper placement essential: “It’s less than milliseconds that a scanner picks up the code. If they’re far apart, your cashiers won’t catch the 2D. We want it to be the primary. Be sensitive to the 50 millimeter rule — closer is better.” Even Kenvue’s Christopher noted that retailers like Wegmans are asking for codes to be placed “very close to the 1D” barcode.

Real-World Testing: From Pilots to Scale

Coca-Cola strategically tested this technology on Topo Chico Sabores Passionfruit drinks rather than flagship brands. The Topo Chico cans feature both traditional barcodes and QR codes serving dual purposes: store checkout scanning and consumer product information through SmartLabel technology.

Meanwhile, Kenvue (maker of Band-Aid and Tylenol) is already operating at scale with 2D codes on 200-300 SKUs. Prakash Christopher, Director of Digital Identification and Traceability at Kenvue, sees dynamic QR codes as powerful storytelling tools. “Your story might not be ready when you launch the product. But through the 2D code, you can continuously add digital content without changing the artwork. That’s a pretty big value for us.”

However, both companies discovered that proper implementation requires coordination across multiple teams and careful attention to technical specifications like code size and placement.

Retailers Are Making This Mandatory

While the industry calls this transition “voluntary,” major retailers are setting requirements. “We’re going to give you a minimum requirement. But what you choose to add, in addition to that, is entirely up to you,” states Chuck Lasley from Dillard’s. Those minimum requirements include a product identifier (GTIN), serial number, and ideally a brand website link.

Wegmans Food Markets is actively preparing supplier communications. “We have not formally notified our suppliers… but we are discussing and talking about a letter to go out,” said Paul Wawrzyniak, Enterprise Systems Manager at Wegmans. The retailer wants collaboration on which application identifiers suppliers will use, recognizing that space constraints limit how much data can fit in QR codes while maintaining scannability.

Benefits Beyond Compliance

GS1 Digital Link offers advantages beyond retailer requirements. For companies, 2D barcodes enable better inventory tracking, faster recall processes, and improved supply chain visibility. During food safety issues, companies can quickly identify specific products for removal based on batch numbers encoded in QR codes.

For consumers, these codes provide instant access to product information, ingredient lists, and allergen warnings. Companies can update this information dynamically without changing the physical package code, creating ongoing engagement opportunities.

Preparing for the Future

The message for packaging professionals is clear; start preparing now, don’t wait until 2027. Companies need to test printing capabilities, train design teams on proper code placement, and coordinate with retail partners on implementation timelines.

The 50mm rule represents one of many technical considerations which requires careful planning. Companies that begin preparation early will be ready when retail partners make 2D barcodes a requirement. Those who wait may find themselves scrambling to maintain shelf space in an increasingly digital retail environment.

How Bar Code Graphics Can Help

Since the first UPC was scanned over 51 years ago, we have provided assistance and solutions to both retailer and manufacturers. Throughout these years, there has been continual refinements to the global identification standards, and we have always been at the cutting edge enabling compliance.

GS1 Digital Link Testing & Certification Services

Our specialized barcode testing division, Identification Labs, is the largest North American facility that provides barcode print quality and compliance services to the industry. We have programs for many of the largest US retailers and annually review over 14,000 barcode submissions for various applications.

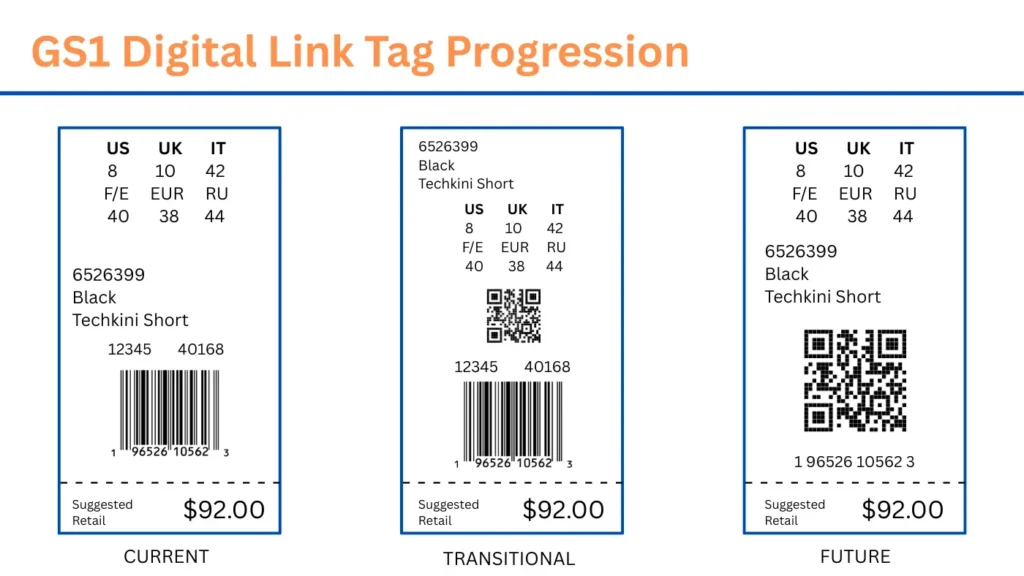

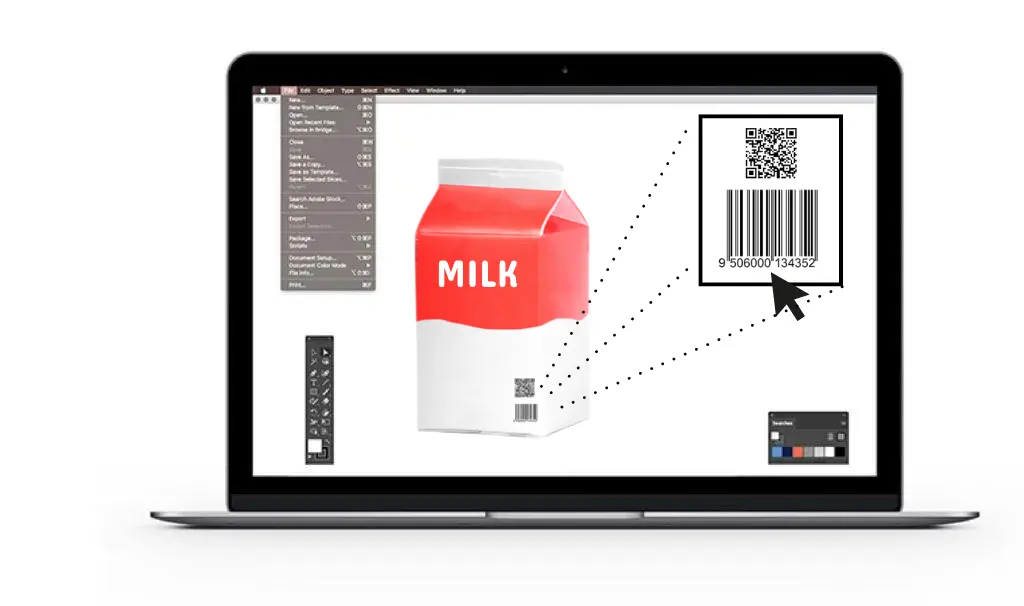

Precision Print-Ready Digital Images: Transitional Format

As noted above, a critical component for seamless point-of-sale scanning of the GS1 Digital Link involves the positioning of the linear UPC/EAN barcode and the GS1 Digital Link QR Code. The foundation of our expertise in barcoding stemmed from our specialization in precise original barcode artwork. The barcode engine that powers our digital web service, PrecisionCode, received UCC/EAN Software certification in 2004. Today our web service provides over 2 million digital barcodes annually. The web service is now capable of providing the transitional format of a linear and 2D barcode as a single graphic file and automatically maintains the necessary 50mm maximum distance that will be required by retailers for trouble-free scanning.

For more information on our specialized web services, please email sales@barcode.graphcs .

GTIN.cloud | GS1 Support Now Supports Dual Transitional Format

Accurate GTIN assignments, product data, and precise barcodes aren’t optional—they’re essential for product identification, compliance, and supply chain efficiency. Our GS1 Support subscriptions ensures that companies assign, format, and manage their UPCs and GTINs flawlessly.

GS1 Barcode Support programs include access to the UPC management portal, GTIN.cloud, and an assigned personal consultant who will review your GTINs and associated product data BEFORE being published. Having a certified consultant assist in managing your GTINs and data, will eliminate inaccuracies and be there to address GS1 standards complexities. Our consultants are currently working on Digital Link strategies with their clients and as of July 2025, subscribers can download dual transitional formatted GS1 Digital Link files.

Comments are closed.