The Critical Role of Print-Ready Barcode Files with Bar Width Reduction

Today’s digital world of retail and supply chain management, barcodes are the unsung heroes that ensure seamless product identification and tracking. However, not all barcode files are created equal. The quality and precision of digital barcode artwork, particularly in high-resolution Encapsulated PostScript (EPS) format with bar width reduction (BWR), can make or break a product’s scannability and compliance with global standards. This article explores why print-ready barcode files with proper bar width adjustment are essential for businesses, delving into the technical nuances, industry standards, and the risks posed by subpar alternatives. The details of barcode compliance are swamped by misinformation from online resellers and even GS1 US (that is not a typo).

Understanding Barcode Artwork and Print Challenges

Barcodes, such as UPC-A, EAN-13, or ITF-14, encode critical data like Global Trade Item Numbers (GTINs) in a machine-readable format. For a barcode to function effectively, it must be printed with precision to ensure scanners can read it reliably at point-of-sale terminals, warehouses, or distribution centers. However, the printing process introduces challenges, notably print gain—the tendency for ink to spread, causing bars to appear wider than intended. This can distort the barcode’s carefully calibrated bar and space patterns, leading to scanning failures, manual data entry, and costly retailer chargebacks.

To counteract print gain, high-quality barcode artwork incorporates bar width reduction (BWR), a deliberate adjustment that slightly narrows the bars in the digital file. This preemptive tweak compensates for the expected ink spread, ensuring the printed barcode aligns with the precise dimensions required by GS1 General Specifications. Section 5.12.4.2 (Barcode master image production) provides the definition and relevance of bar growth compensation. Without BWR, even a high-resolution barcode file risks producing a symbol that fails to scan, undermining supply chain efficiency and consumer trust.

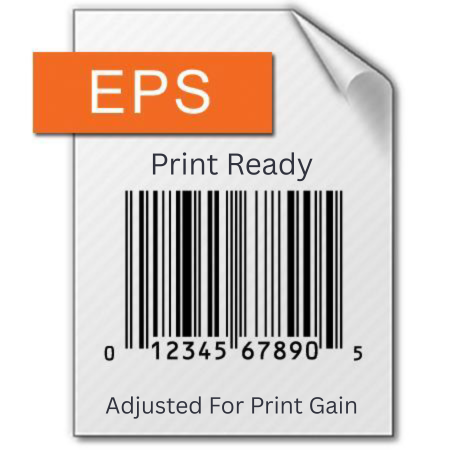

The Gold Standard: High-Resolution EPS Files With BWR

When it comes to digital barcode artwork, the file format matters. EPS files are the industry standard for print-ready barcodes because they are vector-based, resolution-independent, and capable of maintaining precision at any scale. Unlike raster formats like PNG or TIFF, which can pixelate or lose clarity when resized, EPS files ensure that barcode lines remain crisp and accurate, even when printed at high resolutions (e.g., 2540 dpi) required by techniques like offset, flexographic, or silk-screen printing.

Moreover, EPS files are uniquely suited to incorporate BWR. The vector format allows for fine-tuned adjustments to bar widths, measured in fractions of a millimeter, to account for the specific print gain characteristics of different printing methods and substrates. For example, a barcode printed on corrugated material for an ITF-14 case label may require different BWR settings than one printed on a glossy retail package. This level of precision is critical for meeting GS1 standards and ensuring scannability across diverse environments.

GS1 Certification and Industry Standards

The GS1 organization sets the global benchmark for barcode standards, ensuring interoperability and reliability in supply chains worldwide. In 1997, the Uniform Code Council (now GS1 US) published the “UCC Guidelines for Providers of EAN/UPC Symbol Design Software,” outlining the requirements for creating compliant barcode artwork. These guidelines emphasize the need for high-resolution files with BWR to compensate for print gain, a principle that remains central to the GS1 General Specifications today.

Our company takes pride in being the only provider to receive UCC/EAN certification in 2005 for a software engine specifically designed for digital barcode artwork. Our engine, built from the ground up to adhere to GS1 specifications, produces EPS files that are meticulously crafted to include BWR tailored to the client’s printing process. This certification underscores our commitment to delivering barcodes that not only meet but exceed industry standards, ensuring flawless performance in real-world applications. Today the relevant global guideline is ISO/IEC 15419 and functions of barcode production software.

The Risks of Uncertified Barcode Files

Despite the clear need for precision, not all barcode providers prioritize quality. Even GS1 US has introduced digital barcode files through its Data Hub platform, offering SVG and EPS formats without bar width adjustment. These files, while convenient, lack BWR and fail to meet the rigorous standards required for print-ready artwork. The absence of disclaimers about these limitations is concerning, as businesses may unknowingly use these files for packaging, only to encounter scanning issues downstream. EPS barcodes that do not include BWR, even from GS1 US, are not to be used for barcode print production, as per the GS1 General Specifications.

SVG files, primarily designed for web use, are ill-suited for high-resolution printing. They use RGB color spaces and lack the precision needed for BWR, making them prone to distortion when scaled or printed. Similarly, the EPS files from GS1 US Data Hub are described as low-resolution and lacking necessary bar width adjustments, rendering them inadequate for professional printing. Using these files can lead to non-compliant barcodes, increased error rates, and penalties from retailers who demand GS1-compliant symbols. Companies who do not subscribe to GS1 Barcode Service subscriptions can generate high resolution .eps barcode files with bar width reduction from www.createbarcodes.com for $10 per file.

Real-World Implications for Businesses

The consequences of using substandard barcode files extend beyond technical failures. A barcode that fails to scan at checkout can frustrate customers, erode brand trust, and result in lost sales. In warehouses, unscannable barcodes slow down operations, requiring manual intervention and increasing labor costs. Retailers often impose chargebacks for non-compliant barcodes, adding financial strain. For companies aiming to sell through major platforms like Amazon or Walmart, which validate GTINs against GS1 databases, compliance is non-negotiable.

High-quality, print-ready EPS files with BWR mitigate these risks. By accounting for print gain, these files ensure that barcodes scan reliably, even under challenging conditions like low-light warehouses or high-speed retail checkouts. They also align with GS1’s “Verified by GS1” initiative, which helps retailers confirm the authenticity and accuracy of product data, further enhancing supply chain trust.

Best Practices for Barcode Implementation

To maximize barcode performance, businesses should follow these best practices:

- Choose Certified Providers: Work with providers like ours, whose GS1-certified software ensures compliance and incorporates BWR. Avoid uncertified files from platforms like Data Hub and free online barcode generation tools.

- Use EPS for Printing: Opt for high-resolution EPS files over SVG or PNG for all print applications. Ensure the files are placed in design software like Adobe Illustrator or InDesign, not image editors like Photoshop, to preserve vector quality.

- Verify Print Quality: After printing, use barcode verifiers or request a GS1 verification report to confirm scannability. Regular checks prevent issues from ink spread or plate registration errors. IdentificationLabs is our barcode testing lab. Click here to learn more.

- Educate Your Team: Train staff to recognize the importance of BWR and proper file formats. Awareness of GS1 standards can prevent costly mistakes during packaging design.

Conclusion: Precision Is Non-Negotiable

In an era where supply chain efficiency and consumer trust are paramount, the quality of barcode artwork cannot be overlooked. Print-ready EPS files with bar width reduction are not just a technical requirement—they are a strategic necessity for businesses aiming to thrive in competitive markets. By choosing certified, high-resolution barcode files that adhere to GS1 standards, companies can ensure scannability, compliance, and operational excellence. As the industry evolves, let’s prioritize precision over convenience, rejecting uncertified alternatives that compromise quality.

To learn more about barcode file formats and how to use them, please visit https://www.barcode.graphics/digital-barcode.

Comments are closed.