The Top 5 Frequent Thermal Printing Barcode Problems and How They Can Be Prevented

When shipping to any major trading partner, it is essential to closely monitor your print quality. Barcodes with print quality issue could cause severe disruptions in the supply chain, leading to delays, compliance warnings, and potentially chargebacks.

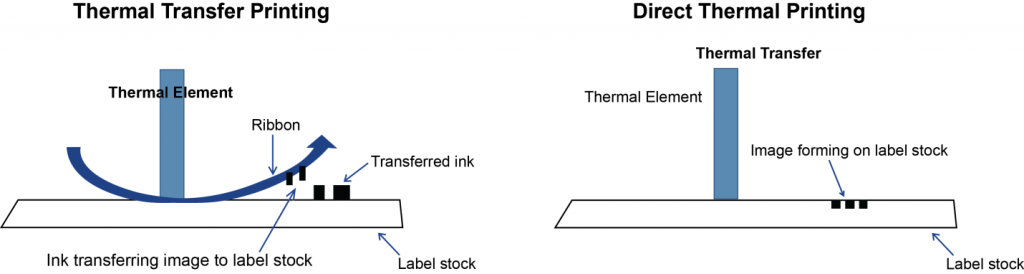

Thermal transfer vs. direct thermal

Thermal transfer printing utilizes a ribbon to create a printed image on label stock. The printer applies heat to the ribbon, which transfers the wax and/or resin onto the label.

With direct thermal printing, heat is applied directly from the print head to the label stock, causing the stock to blacken resulting in the image. Although direct thermal is quite cost effective, the labels may not always be able to withstand the shipping process compared to thermal transfer printed labels. Direct thermal labels are heat-sensitive, and the printed image can degrade in hot environments. Be sure to keep this in mind when shipping to warehouses in hot climates, or wherever there’s a possibility for label stock to be exposed to sunlight for long periods of time. For shipping applications, select a direct thermal stock with a protective coating.

Heat settings

In order for a barcode symbol to be recognized by a scanner, there must be an adequate contrast between the dark bars and light spaces.

If a barcode appears to smudge and the bars are printed very thickly, it may because the print speed is too slow, or the darkness/heat settings are too high. Bars bleeding into the white spaces will hinder an adequate scan of the barcode.

In contrast, if the bars of a barcode appear faded, you may want to increase your heat setting, or slow down the printing speed.

Printer maintenance

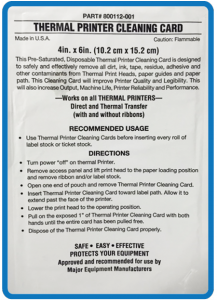

If you notice “white spots” distributed throughout your barcodes, this may be due to a dusty roller. Vertical gray lines can also appear due to residue on the rollers.

It is recommended that your label printer is receives routine maintenance and cleaning to avoid these issues. Bar Code Graphics recommends a thermal printer cleaning card which is run through the print path of the printer and will effectively remove impurities, such as dust from thermal print heads. Additionally, a thermal printer cleaning pen can be used conveniently on the print head surface. Compressed air can be used to clear away excess debris, or a q-tip dabbed in isopropyl alcohol can be used to clean surfaces directly.

A print head burn is a straight void cutting through a barcode. You’ll notice with a shipping label for graphic that the white line is thin and runs from the top to bottom of the label. A print head is a consumable part of a thermal printer, and must be cleaned and replaced as needed.

If you notice burn lines on your label, it’s time to promptly replace your print head. It is best to have a replacement print head on hand. Always be sure to review your print head manufacturer’s lifetime estimates.

Wrinkled ribbon

A wrinkled ribbon will cause a diagonal streak throughout your media, causing voids in your barcodes. Remember, a barcode must have contrast of dark bars and light spaces to be read by a scanner. Even minor voids in the printing will disrupt scanning.

To prevent a wrinkled ribbon, be sure that your ribbon is loaded properly. Most thermal printers have pressure adjustment rods on the print head housing. Uneven spacing and pressure from the rods can create ribbon creases.

Print Head Burn

A print head burn is a straight void cutting through a barcode. You’ll notice with a shipping label for graphic that the white line is thin and runs from the top to bottom of the label. A print head is a consumable part of a thermal printer, and must be cleaned and replaced as needed.

If you notice burn lines on your label, it’s time to promptly replace your print head. It is best to have a replacement print head on hand. Always be sure to review your print head manufacturer’s lifetime estimates.

Mismatch of ribbon and material

If the entire label is too light, you may have a discrepancy between ribbon and media.

If the ribbon ink is “flaking” or scraping off, your ribbon and media may be incompatible, and you may want to test other combinations.

Prevention Procedure

To avoid the five common disruptions in thermal print quality, Bar Code Graphics recommends that a quality assurance protocol be set into place in your printing environment. Visual inspection in the morning, or when printers are first turned on is highly recommended. Print out a sample label and inspect thoroughly for any of the above print quality issues. A daily log should be maintained.

Prior to sending out a large shipment to any major retailer, it is recommended to send your label to a barcode testing lab for verification. Identification Labs, a division of Bar Code Graphics is comprised of GS1 Certified Professionals and Certified Consultants. These GS1 Professionals evaluate print quality based on ISO/ANSI parameters, provide specific information on correcting any issues, and can also test against specific retailer requirements.

This article was written by Erica O’Kelly. Erica is a member of the Identification Labs compliance team and is a GS1 Certified Barcode Professional. Illustrations provided by Lori Williams from our graphic design department.

Comments are closed.