A verifier is an important piece of equipment and something many companies consider essential for their barcode quality assurance. What many companies might not be considering is the work that needs to be done to ensure the verifier is delivering accurate results.

What should you be doing? As an Axicon reseller, we’ve found their documentation and commitment to accuracy to be the best in class. We will focus on Axicon equipment, but most of this applies to all verification equipment.

Regular calibration – Axicon documentation recommends weekly to monthly calibration with the included calibration card. Calibration ensures that equipment light levels are properly accounted for. Light sources in verification equipment WILL drop off over time so calibration is a must.

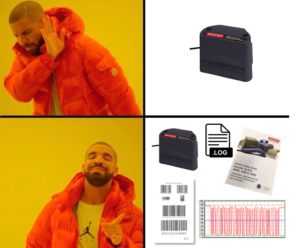

IQ/OQ/PQ testing – This kit from Axicon allows companies to verify that their equipment is functioning correctly by analyzing scan results from specially designed test cards. Many pharmaceutical/medical companies require this, but it is a worthwhile kit for any company relying on accurate verification.

Factory recalibration – Occasionally a verifier will need to be returned to the manufacturer for recalibration and cleaning. Axicon recommends this be done annually. Use of an IQ/OQ/PQ kit can help companies determine when factory calibration is needed.

Selecting the right verifier – All verifiers have limitations to the size of barcodes that they can verify. This is determined by the aperture of the verifier, and the right aperture needs to be selected according to the size of the barcode. A verifier with the wrong aperture may still be able to read a barcode that is too big or too small, but the results will not be accurate. Grades could be either too forgiving or too strict.

Logging results – The verification software we use all allow for logging of results. This is a useful feature for ensuring that verification is happening, and to identify trends over time. Drastically swings in trends could indicate a production problem or problem with the verifier itself.

Compare results – At Bar Code Graphics, we have the benefit of using several different models of verifiers, and barcode samples are frequently tested on more than one device. This allows us to compare results between verifiers. Significant differences are a flag that one or both of the verifiers needs calibration or adjustment.

Training! – A verifier is a powerful tool, but in the hands of an uninformed operator results can be confusing or counter-productive. At a minimum, users should have a general understanding of ISO/ANSI parameters, proper handling and verification procedures, and calibration and maintenance intervals. For our verifier sales, we include a 30 minute training call and presentation covering these topics.

Environment and handling – some general considerations for installation and handling:

- Dedicated location for verifier. Cables routed to avoid trip/fall risk

- Plug verifier directly to the PC. USB hubs or abnormal USB port power can interfere with accurate results.

- Installation in a location with consistent lighting

- Installation in a low dust environment

- Frequent cleaning of glass window for “flat bed” verifiers

- Careful handling of all verifiers (no dropping, no bumping)

- Verifiers are placed in their cases if moved out of the testing lab

There is a lot that is required to make sure verification equipment is providing accurate results. If you are interested in purchasing a verifier, make sure you have a plan for training, integration, and ongoing maintenance. If you have a verifier but are concerned that your practices are lacking, contact us for training information. Even if you have outsourced your printing, you need to be asking if your printer is taking all of the necessary steps to ensure quality barcodes.

For companies that don’t have the time or experience, Bar Code Graphics offers verification services for all types of barcodes. We have robust quality control processes in place, with ongoing training and strict maintenance routines. Click below for more information:

About The Author

Brien Fennell is a divisional manager at Bar Code Graphics for over 10 years. Brien develops and manages barcode compliance programs for a variety of industries. He has passed numerous GS1 certifications ranging from barcode print quality to digital content. As a leading authority on barcode structure and compliance, Brien has authored numerous industry and trading partner barcode guidelines.

Comments are closed.