Frequency of GTIN & GS1-128 of Barcode Certification

Barcodes serve as the critical communication link between manufacturers and retailers. Yet many businesses operate under the misconception that barcode quality assurance is a one-and-done process. This approach can lead to costly scanning failures, compliance violations, and disrupted operations when you least expect them. The harsh reality is many suppliers only address routine barcode testing AFTER the compliance charges start amassing.

At Identification Labs, the barcode print quality evaluation division of Bar Code Graphics, we regularly encounter suppliers who discover barcode failures only after their products reach retail shelves or distribution centers. These costly disruptions stem from a common oversight: treating barcode quality as a one-time validation rather than an ongoing operational requirement that must adapt to changing business conditions.

The Critical Changes That Demand Barcode Testing

New Product Launches and Package Redesigns

Every new product introduction or package modification represents a potential barcode vulnerability. Design teams often focus on aesthetic appeal while overlooking print quality parameters that directly impact scannability. When artwork undergoes revision, substrate materials change, or package dimensions shift, the barcode’s performance characteristics can be significantly affected.

Consider the common scenario where a manufacturer switches from glossy to matte packaging. This material change alters light reflectance properties, potentially pushing contrast ratios below acceptable thresholds. Without proper testing using ISO/IEC 15416 standards for linear barcodes or ISO/IEC 15415 for two-dimensional codes, these issues surface only when scanning problems emerge at retail locations.

Software and Hardware Transitions

Production environment changes create another critical testing trigger. When manufacturers upgrade printing equipment, modify software parameters, or transition between suppliers, barcode output characteristics inevitably shift. Print density variations, registration accuracy, and dimensional consistency can all be impacted by these operational changes.

We’ve observed cases where seemingly minor printer calibration adjustments resulted in quiet zone violations or symbol dimension deviations. These technical variations might not be visible to the naked eye, yet they can cause scanning failures that disrupt entire supply chains. Regular testing following any production system modification helps identify these issues before they impact trading partner relationships.

Material and Substrate Modifications

The substrate beneath your barcode significantly influences print quality outcomes. Whether driven by sustainability initiatives, cost optimization, or supplier availability, material changes require comprehensive evaluation. Different substrates exhibit varying absorption rates, surface textures, and reflectance properties that directly affect barcode readability.

Recent sustainability trends have prompted many companies to adopt recycled materials or alternative packaging solutions. While environmentally responsible, these changes can introduce print quality challenges that standard visual inspections cannot detect. Specialized testing equipment and methodologies aligned with GS1 General Specifications become essential for validating performance across these material transitions.

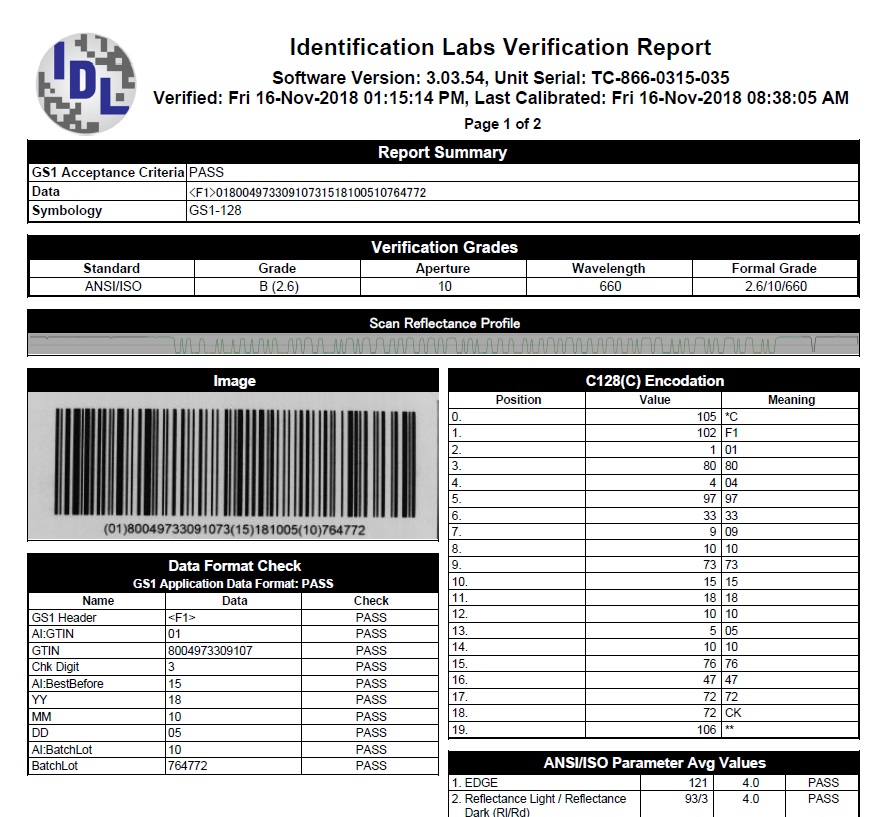

Understanding Testing vs. Certification Requirements

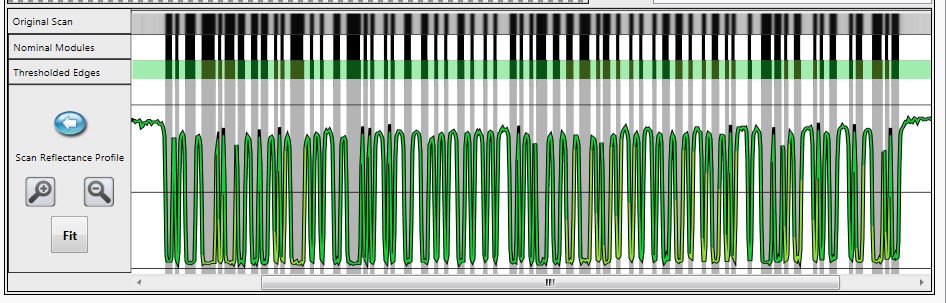

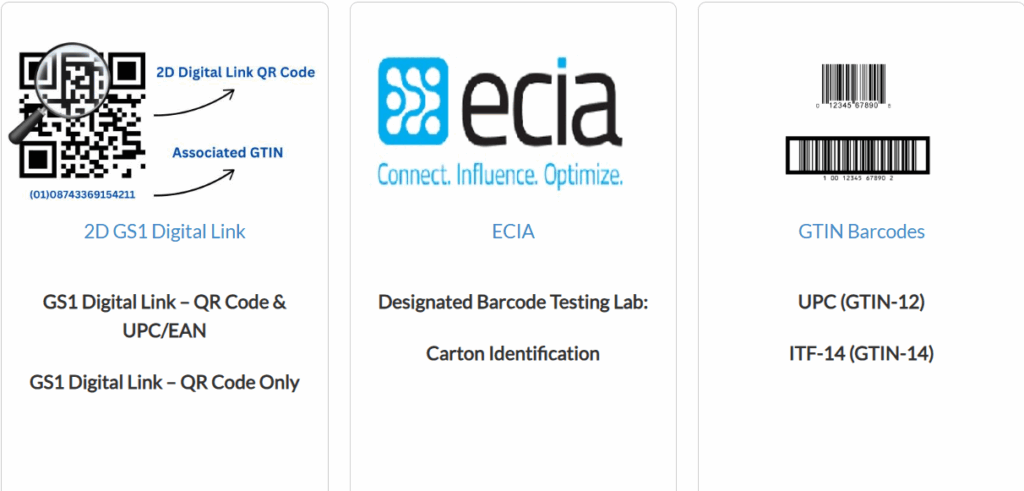

Barcode testing focuses on evaluating print quality against established ISO standards, examining attributes like contrast, minimal reflectance, symbol dimensions, quiet zones, and data accuracy. This process identifies potential functionality issues that could prevent proper scanner recognition or result in data encoding errors.

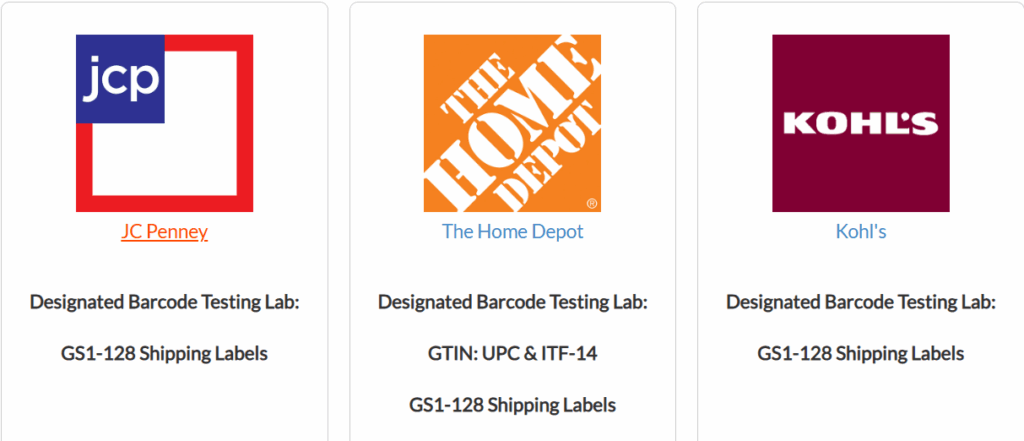

Certification extends beyond basic testing by validating compliance with specific industry or retailer requirements. For instance, Home Depot suppliers must satisfy both GS1 Standards and Home Depot’s proprietary dimensional and print quality thresholds for their GTIN barcodes and SSCC-18 shipping labels. These requirements often exceed basic ISO standards, reflecting specific operational needs within particular retail environments.

The distinction becomes particularly important when suppliers work across multiple retail channels. A barcode that passes ISO testing might still fail certification requirements for specific retailers, highlighting why comprehensive evaluation services are essential for maintaining trading partner relationships.

The Business Case for Routine Testing

Supply chain disruptions caused by barcode failures carry significant financial implications. Retailers increasingly implement compliance penalties for non-performing barcodes, while operational delays can cascade through entire distribution networks. Regular testing serves as insurance against these preventable costs.

Moreover, trading partners are becoming more sophisticated in their barcode quality expectations. Since 2011, Home Depot has required suppliers to test every GTIN packaging variant to help mitigate supply chain an checkout disruptions. Suppliers who establish routine testing protocols demonstrate operational maturity and commitment to supply chain reliability.

Implementing Effective Testing Protocols

Successful barcode quality management requires systematic approaches that balance thoroughness with operational efficiency. Key considerations include establishing testing triggers around production changes, maintaining relationships with our testing team, and developing internal quality control processes that complement external validation services.

Documentation plays a crucial role in this process. Maintaining records that link testing results to specific production runs, material lots, and equipment configurations enables rapid problem isolation when issues arise. This systematic approach transforms reactive problem-solving into proactive quality management.

The integration of barcode testing and certification creates a comprehensive quality assurance framework that protects against operational disruptions while maintaining compliance with trading partner requirements. Rather than viewing these processes as burdens, forward-thinking organizations recognize them as competitive advantages that enable reliable, efficient supply chain operations.

Comments are closed.