As the US authority on barcodes, companies contact us every day inquiring either how to go about barcoding their products or for help unraveling a problem with the barcodes currently on their packaging.

Whereas a logo and brand style might entice a consumer to purchase a product, a barcode that cannot be scanned will prevent present and future purchases. Sales will be not be recorded by the retailer and they will not know to place a reorder. Furthermore, retailers and marketplaces assess penalties to suppliers for non-scannable UPCs. Barcoding mistakes are completely preventable once you know what to look out for.

Common Barcoding Mistakes – UPCs

The UPC barcode has been around for over 45 years. UPCs are on millions of products around the globe. Anyone reading this right now could probably find a dozen real life UPCs in just a few minutes. And yet, there are still countless ways to mess them up. You think we’d have them figured out by now!

Well, we have… but that’s our job. We have worked with tens of thousands of companies either figuring out that implementing UPCs isn’t as easy as it seems or trying to figure out where thing went wrong. For as long as they’ve been around and as common as they are, here are the 5 most common UPC mistakes:

Barcode Sizing Too Small

If you know a graphic designer who hasn’t tried to make the UPC smaller, we’d love to invite them to dinner. Bigfoot, the leprechaun from Lucky Charms, and my invisible friend from childhood will all be there.

UPC barcodes have a defined sizing range for the width and height dimensions. These dimensions, particularly the minimum sizing, are based on limitations of the scanners used to read the UPC and the printing technology used to create them. Smaller barcodes have tighter print tolerances and can be problematic for scanners. Also, reducing the height of a UPC has a negative impact on scanning performance.

To view a sizing table for UPC barcodes, please visit https://www.barcode.graphics/tools-upc-sizing-chart/.

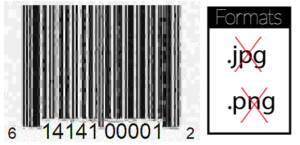

Bad Barcode Origination

Using the wrong type of file format, like a .PNG could result in a barcode that looks ok but cannot be scanned. Scaling or converting a UPC file can distort the precise sizing and bar patterns that are needed for a good scan. The result is a barcode that scans “fine” on your phone but is going to reject when it hits the point of sale scanner at your biggest account.

All digital barcode artwork should be created as a vector image to maximize the resolution of the barcode symbol and minimize file size. The most common file format used is .EPS and .EMF (for Microsoft software).  To learn more about digital barcode file formats, please visit https://www.barcode.graphics/vector-barcodes/.

To learn more about digital barcode file formats, please visit https://www.barcode.graphics/vector-barcodes/.

A critical component .EPS barcode artwork is Bar Width Adjustment. To compensate for bar growth/reduction which occurs during the print process, digital files (original artwork) must include a bar width adjustment factor. Without this factor, the bars in a barcode will grow excessively and result in a poorly printed symbol.

Wrong Number/Wrong Position

From transposition errors to wrong positioning, all twelve digits of a UPC are just itching to spoil your best laid plans. GS1 terminology and data tables can be confusing and it is very common for companies to confuse the UPC Company Prefix with the GS1 Company Prefix.

Retailers like Walmart will request different data lengths, and different systems will vary in how they assign or handle the check digit. Here’s a common scenario: the GTIN number in your product table is “00614141000012”, but the number in your printed UPC is “061414100001”. It is important to noes that many companies make similar mistakes when creating case GTIN-14s based off an eaches GTIN-12.

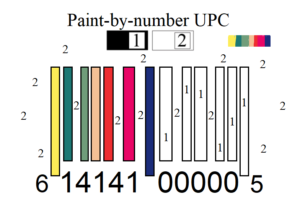

Incorrect Color used for Bars and/or Spaces

Along the same lines as sizing, there isn’t a graphic designer who hasn’t wondered “couldn’t we make the UPC, you know, more fun?”. Certain color combinations, as pleasing to our eyes as they may be, just won’t work.

Scanners need to dark bars (low reflectance) on a light (high reflectance) background. Although you cannot go wrong with black bars printed on a white background, there are numerous color combinations which work fine. For guidance on barcode color selection, please visit https://www.barcode.graphics/upc-color-guide/

Incorrect Placement

We’ve all stood at check out lines long enough that we should know the basics of UPC placement by heart, but sometimes it’s not so easy, sometimes it’s an unusual product shape, and sometimes your good sense was just on vacation that day.

Placement issues can also involve folds, tape, or over labeling. The GS1 General Specification has explicit guidelines for UPC placement on most types of products/packaging. Although the document is very technical, it may be reviewed at https://www.barcode.graphics/tools-gs1-general-specs/

How Can We Help?

If you are just getting started with UPC barcoding, our GS1 Barcode Service provides the necessary comprehensive assistance enabling you to correctly assign UPC barcodes to your products the first time. A dedicated personal barcode consultant will available for one year to ensure your success.

If your company ALREADY licenses a GS1 Company Prefix, our GS1 Barcode Support enables your company to have a dedicated consultant work through all your existing and future UPC assignments. These programs include a credit for either digital barcodes, printed labels or barcode testing. Otherwise companies can submit individual problem barcode samples for testing by visiting https://www.barcode.graphics/identification-labs-certification/ or calling us at 800-662-0701 x250.

To access resources to help prevent barcoding mistakes, please click on the TOOLS heading on the upper right side of this page. Lastly, for companies who print their barcodes in-house, we have a blog post discussing common problems. Click Here to Access.

Post Script – Missing Data

“I brought my barcode to a store and it didn’t scan”

It seems so simple – you have a good UPC, you’ve assigned it correctly, you used the right kind of file, you even printed it in boring old black and white – but you go to a store to try it out and… nothing. The UPC comes up as “not found”. This probably is not a UPC error, but it is common enough that we wanted to bring it up here. Behind the scenes of every scan in every store are charts and tables and transmissions and updates occurring every day. Unfortunately it’s not that simple, but we would love to help.

Comments are closed.